In addition to being excellent electric insulators hybrid bearings have a higher speed capability 1 2 1 5 time limit of rotations compared to steel bearing and will provide longer service life lower friction and a lower level of energy consumption than all steel bearings.

Ceramic hybrid bearings uk.

Ceramic hybrid bearings have a lifetime which is 4 8 times longer than traditional bearings.

Machinery speeds increase as production demands maximum efficiency and reliability with the highest output quality.

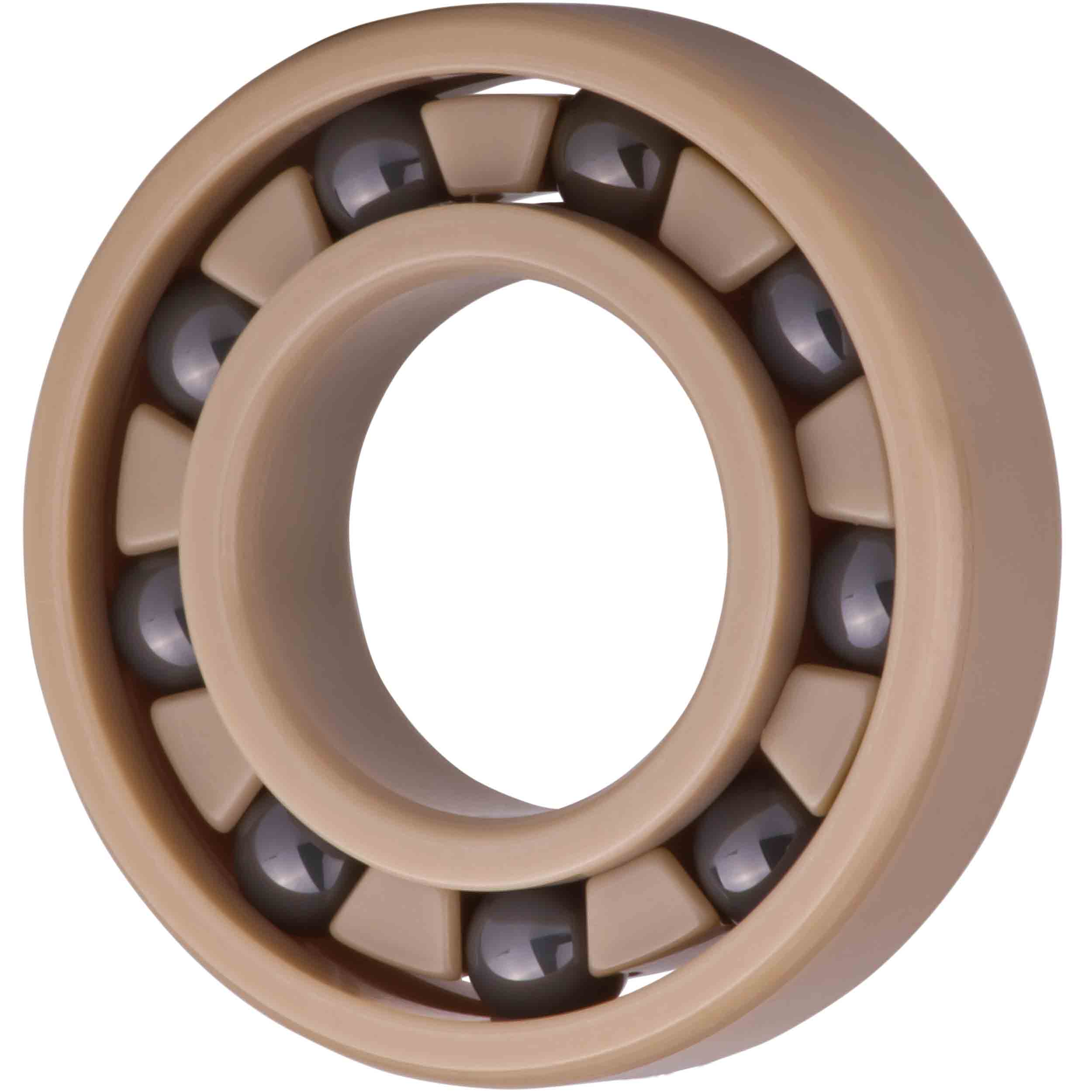

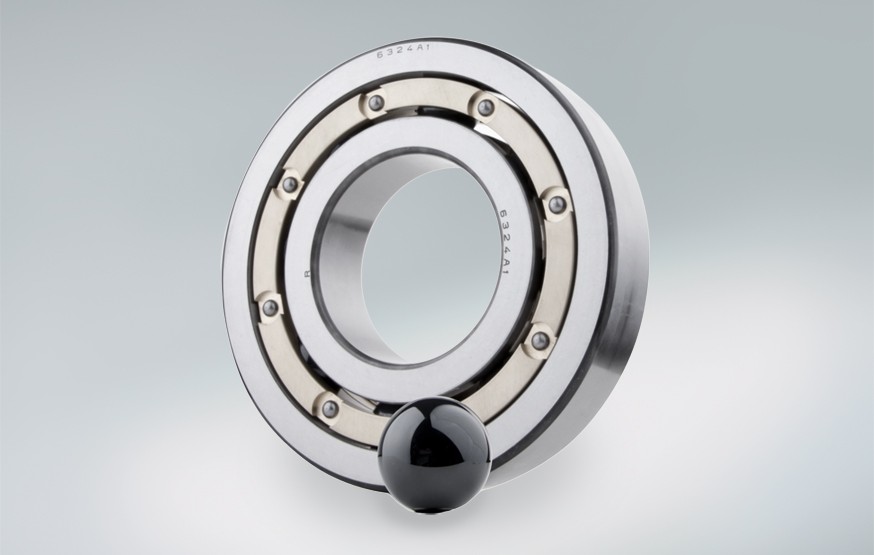

Hybrid bearings have rings made of bearing steel and rolling elements made of bearing grade silicon nitride si 3 n 4 which make the bearings electrically insulating.

Boca bearings is the leader in ceramic and ceramic hybrid bearing technology for industrial and recreational applications.

This enables you to reduce operating costs and increase production efficiency.

These bearings are also non conductive.

These properties result in two key benefits of hybrid ceramic bearings over traditional bearings a 30 50 increase in speed and an increase in the fatigue life of the bearings.

Lower operating temperatures help extend lubricant life and bearings with ceramic balls have been proven to last up to five times longer than conventional steel ball bearings.

As the bearing race rotates it causes the balls to rotate.

Ceramic hybrid bearings also run at significantly lower operating temperatures allowing running speeds to increase by as much as 40 to 50 per cent.

Our ceramic hybrid bearings are supplied with stainless steel rings s440 and balls made from zirconia zro2 or silicone nitride.

The purpose of a radial bearing is to reduce rotational friction and support loads.

We produce ceramic hybrid bearings which consist of stainless steel rings with either zro2 or si3n4 ceramic balls these bearings are very popular with our bicycle motorcycle clients amongst other industries looking for a high performance part.

Silicon nitride rolling elements can extend bearing service life by offering enhanced bearing performance even under difficult operating conditions.

Hybrid ceramic bearings have traditional 52100 steel or stainless steel rings with ceramic silicon nitride si3n4 balls.

Hybrid bearings are constructed of steel inner and outer rings with ceramic rolling elements in place of steel.

The direct benefit to the end user is that fewer breakages means less machine down time increasing output abilities and fewer replacements.

Conventional all steel bearings limit design as technology rolls forward at a fantastic rate.

Ceramic hybrid bearings are available in variety of sizes and styles.