Ceramic bearings offer many advantages over all steel bearings such as higher speed and acceleration capability increased stiffness lower friction and more.

Ceramic bearings for electric motors.

Today we do a quick comparison of two identical cars with the exception of the ceramic bearings and titanium screws.

As with other isolation measures shaft current will seek an alternate path to ground.

Any application that requires higher speeds lower friction and longer life are ideal for ceramic hybrid bearings.

Characteristic fluting caused by electric arcing.

Since these bearings are constructed from many materials they often operate in hybrid capacities.

Long life and the need for minimal lubrication make this material appropriate for extreme applications.

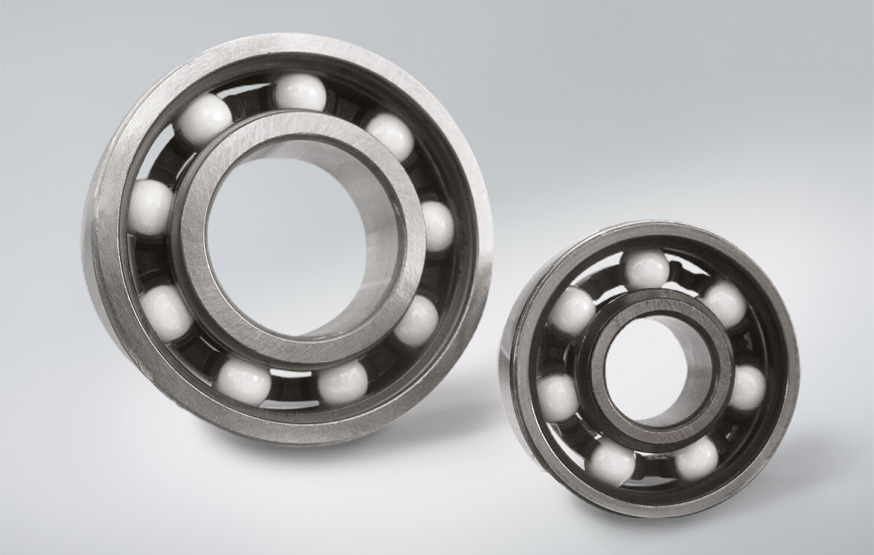

Ceramic hybrid electric motor quality emq bearings have steel races and ceramic balls.

The non conductive silicon nitride ceramic balls in our ball bearings eliminate electrical arcing through the bearing crucial in applications where an electric motor is controlled by a variable frequency drive vfd.

Ceramic balls are also nonconductive.

In most cases motors with ceramic bearings must be special ordered and have long lead times.

All motors go down the same assembly line and it is just easier to put the fittings on every.

The use of nonconductive ceramic bearings prevents the discharge of shaft current.

Ceramic hybrid bearings are widely used in electric motors aerospace applications performance racing vehicles laboratory equipment under water applications and more.

Bearings coated with a ceramic insulating material stop electric arcing inset.

Bearing and motor manufacturers have given various reasons as to why grease fittings are installed on bearings and motors that have sealed bearings such as.

The motor end cap supports the bearing outer race.

This technology is costly.

Ceramic bearings are typically constructed with a ferrous inner and outer ring or race with ceramic balls in the place of steel.

Ceramic balls are suitable for applications where high loads high speeds and extreme temperatures are factors.

These bearing operations enable fresh grease to reach the bearing and push out excess grease.

Ceramic hybrid ball bearings last longer.

Ceramic hybrid bearing styles and sizes.